Universal testing Machine (Tensile testing Machine) of 60 M.T. Capacity with calibration up-to-date has been commissioned for determination of tensile strength, yeild stress and percentage of elongation. With the help of this machine, one can hold bend test with required sizes of mandrels. Charpy Impact Testing Machine With Sub-Zero Both(-50°C)calibration up-to-date has been commissioned for determination of Impact Value.

Laboratory within the premises of the plant is set-up having facilities to determine elements like carbon, manganese,sulphur, etc. as per requirement of relevant BIS and other standards. Determination of elements are being done by volumetric test i.e. titration method. The Plants can also undertake elementary testing by spectro Analysis from our sister concern Shri Bajrang Power & Ispat Limited.

Since the production has been managed by the most scientific and technical devices, the entire process is automatic which helps in maintaining best quality end-products controlling the cost of production to reach the consumer at most reasonable and competitive prices through out the country. Wide marketing network, well organized and experienced technical persons are recruited to interact with the consumers. Shri Bajrang Alliance Ltd. is located in the heart of the country hence the transportation is not only available easily, besides this the location of the Mill is in the District Town having facilities of conveyance like Bus, Train, Air and Taxi services either to visit the Mill or to meet the consumer within least possible period. Shri Bajrang Alliance Limited factory is up-to-date with its communication facilities like latest computer network, internet, email and fax etc. Most of the Nationalized Banks have their branches in Raipur.

This unit has established its Quality Assurance Plan and in practice for strict/ rigid on – line stage inspection, sampling and testing is to be done as Scheme of Testing under qualified technical staff.

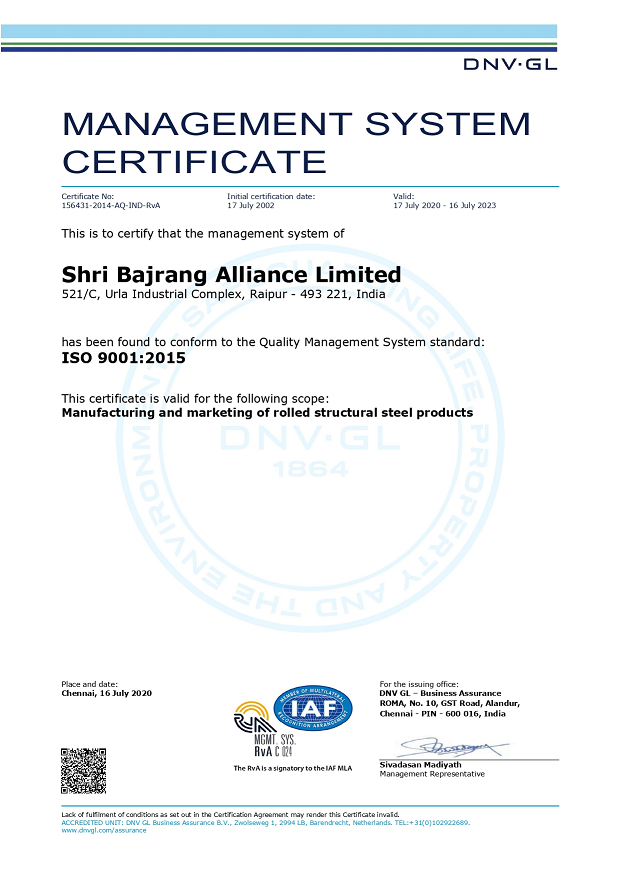

The unit has been certified by for ISO:9001/2015 for Quality Management System and on-line system monitoring &achieving new targets every moment towards development.

Highly qualified and renowned persons are associated with this unit having track record experience in the field of structural Re-rolling mill for ensuring quality product.

Since the mill is fully automatic and on fiber bearing, the finishing time is reduced considerable so as to maintain material temperature at finishing stage in avoidance of defamation. Speedy finish enhancing the surface finish and ensuring quality products.

Since no man power is involved during the stage of production, the handling of bigger and heavier places for rolling process no problem offering fix –length to consumers thereby, reducing wastage to the end users.

Billet / Bloom / Slab with confirmed chemistry as per relevant specification are being mainly procured from Prime Producers so that finished products would conform to the required standards and to meet costumer’s need.

A Full fledged Quality Control Department equipped with modern amenities & well qualified staff which carries out the task of inspection and testing to assure the quality of product as per relevant BIS norms in its Scheme of Testing & Inspection.

All the test apparatus re cheeked and calibrated regularly by the approved agency and Calibration are kept for kind submission on demand.