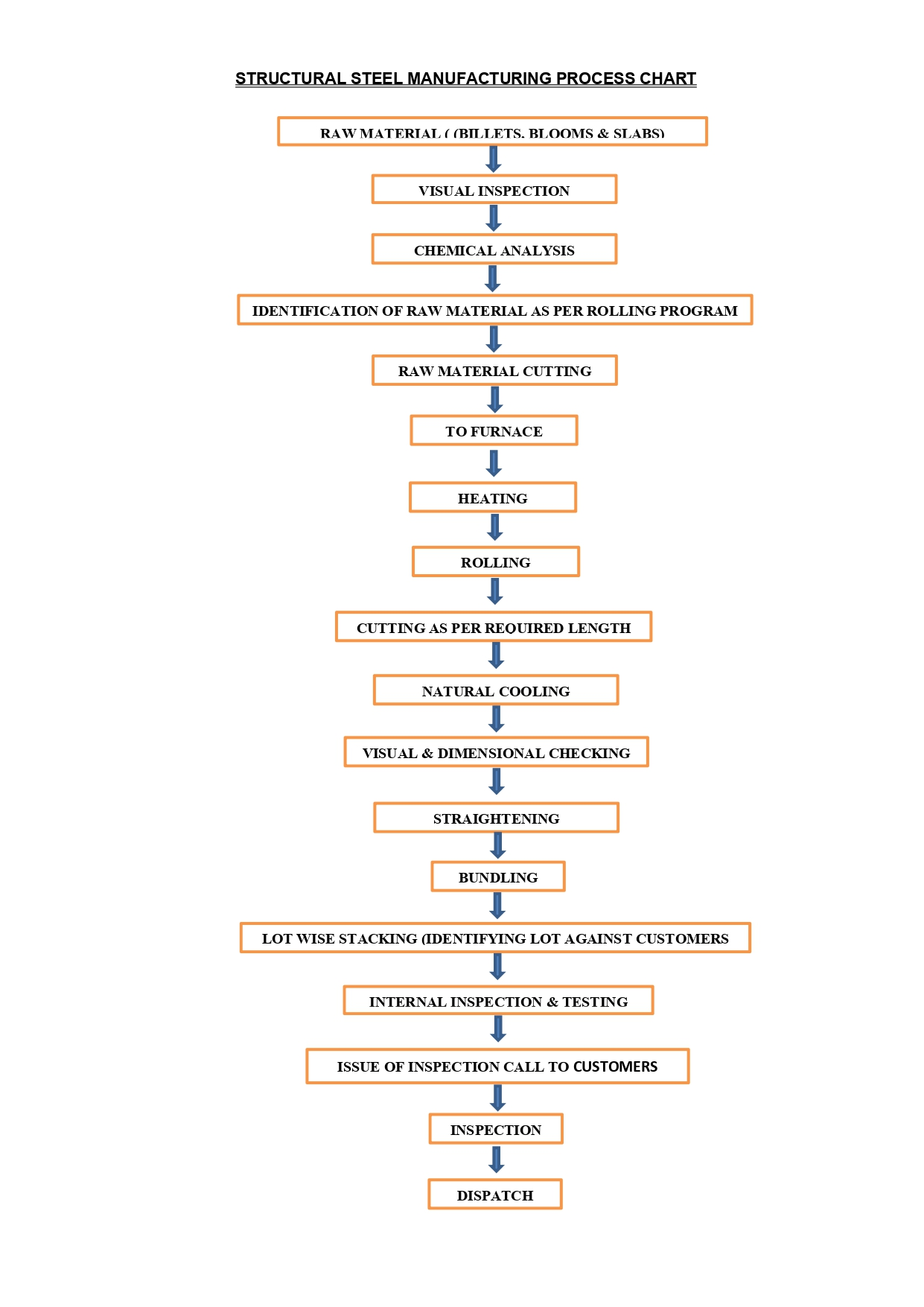

Tested raw-materials grade/cast – wise are dressed & cut into required size for taking into production of finished structural Grade/Cast-wise raw-materials are charged into the furnace by Hydraulic Pushers.

Furnace temperature is checked on hourly basis by optical Pyrometer / Temperature indicators duly provided for each zone of the furnace i.e. pre-heating, heating and soaking zone. Rolls & other mechanical appliances are checked before stating of production.

During rolling every care is taken for dimensional check, sectional weight control and visual inspection are conducted. Samples are taken of the finished product every interval as per STI and mechanical, chemical & dimensional checks are conducted. Not meeting the relevant standard as per requirement are sorted out and stacked separately. Finished products conforming to relevant standard are identified accordingly to lot number and samples are drawn for internal testing as per BIS norms. Being satisfied with the quality colour code as specified in the relevant standard is being introduced.

Either 3rd party or end-user carries out pre-delivery inspection at the time of dispatch.